Many technologies are available to process raw & recycled materials at CRM group.

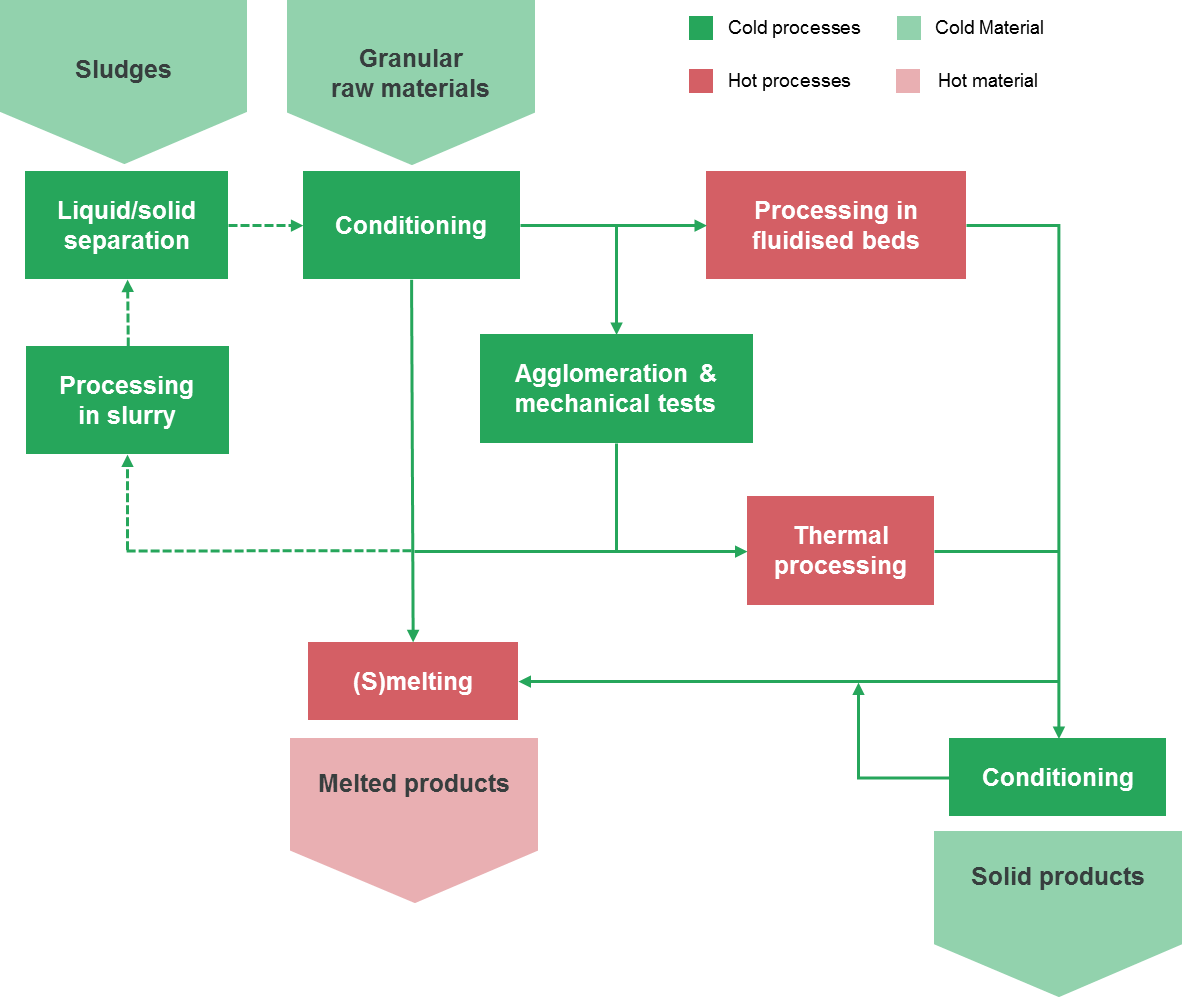

The figure below illustrates the many paths in which unit operations at lab and pilot scale can be sequenced to simulate complete industrial processes.

Granular raw materials cover a wide range of materials, from lumpy to dusty, including ores, solid fuels, scales, swarfs, dusts, shredded residues, dewatered sludges, etc. Cold unit operations mainly include conditioning (on raw materials or solid products), agglomeration, processing in slurry and liquid/solid separation. Hot unit operations include thermal processing, processing in fluidised beds and (s)melting. These operations often generate fumes or gases loaded with dust. Both can be sampled and characterised to contribute assessing process performances.