Several services can be offered

|

Service |

Metalworking |

Assembly |

|

Level #1 Characterization |

|

|

|

Level #2 Optimization |

|

|

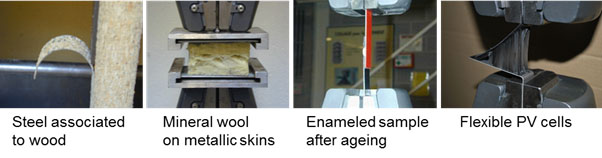

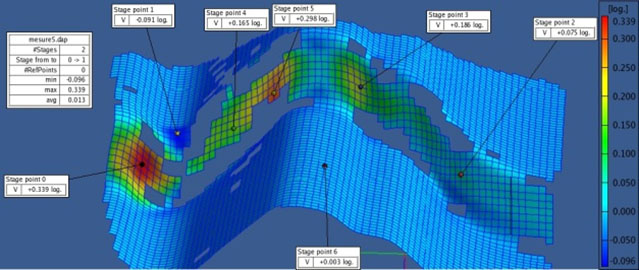

Strain measurement

Forming of Copper

CRMGroup can assess the forming behaviour of materials. Based on these characteristics, it is possible to select the right material grade for the application.

Assembly and dis-assembly of material is a topic more and more important.

CRMGroup can support from the selection of adhesive to the assessment of assemblies regarding ageing tests.

Several services can be offered

|

Service |

Metalworking |

Assembly |

|

Level #1 Characterization |

|

|

|

Level #2 Optimization |

|

|

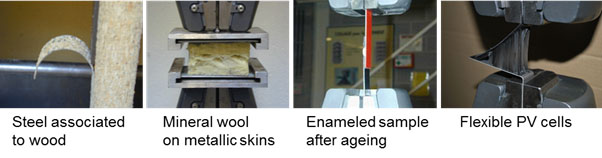

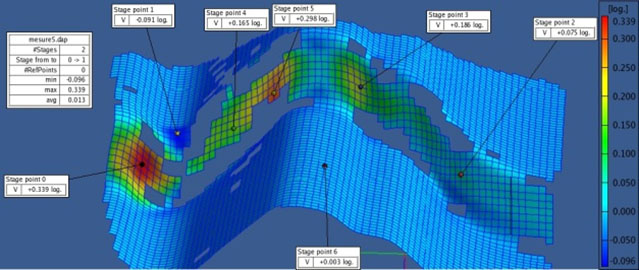

Strain measurement

Forming of Copper