Advancing Thermal Management with PCM Heat Storage Devices

At CRM Group, we are committed to pioneering innovative solutions that push the boundaries of technology and engineering. One of our latest ventures involves the development of heat storage devices (HSD) based on Phase Change Materials (PCM), aimed at ensuring the thermal stability of electronics in space missions and beyond.

Ensuring Thermal Stability for Space Electronics

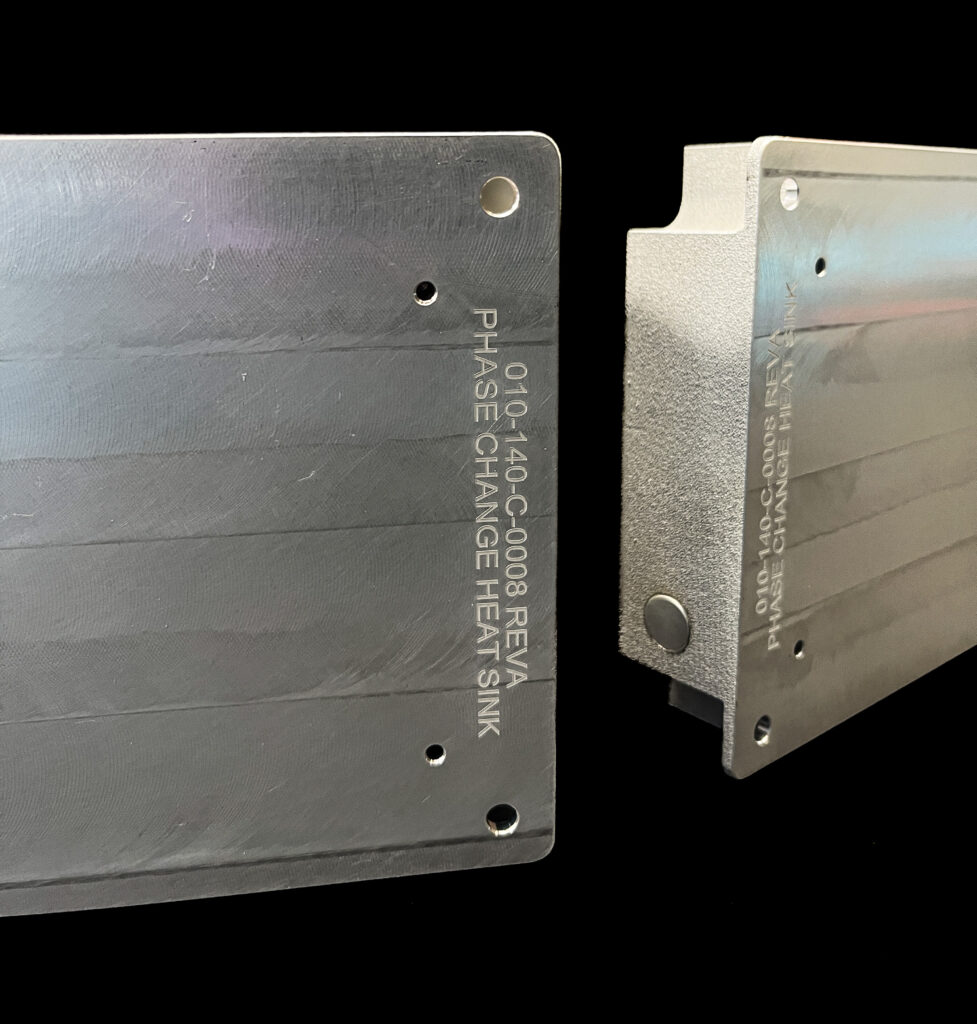

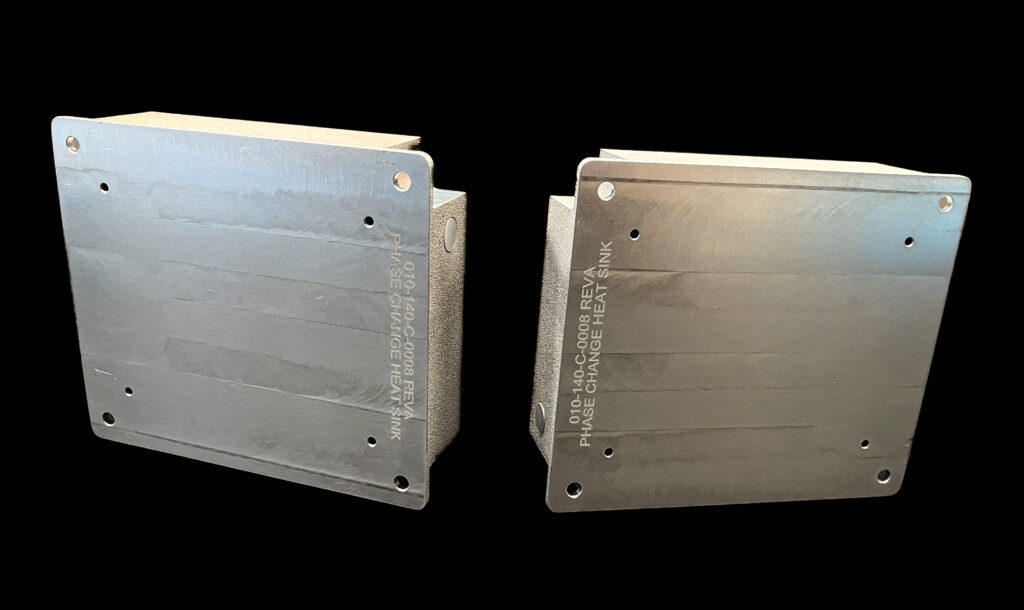

A few months ago, in collaboration with our partners at Walopt, we were able to work on the design of an advanced heat storage unit designed to meet the stringent requirements specified by Airbus Defence and Space. This advanced PCM-based unit is set to play a crucial role in the European Space Agency’s (ESA) Mars Rover mission, enabling longer operational periods on the Martian surface. The PCM-based heat storage unit has been meticulously produced and successfully tested under vacuum conditions, demonstrating its reliability and efficiency. It is currently undergoing further study and testing at ESA/ESTEC, paving the way for future applications.

The Advantages of PCM Heat Accumulation Units

A PCM heat accumulation unit offers several significant benefits:

- Passive Heat Management: PCM devices store and release heat in a completely passive manner, eliminating the need for mechanical components.

- Stable Temperature Control: The design-based switching temperature ensures consistent thermal regulation, crucial for maintaining the operational integrity of electronic components.

- Enhanced Mission Duration: By effectively managing thermal loads, PCM units can extend the operational lifespan of space missions, allowing for more prolonged and reliable data collection and experimentation.

Applications in Space Missions

- Temperature Stability: PCM devices maintain a stable temperature, essential for the delicate instruments used in space exploration.

- No Moving Parts: The absence of moving parts in PCM devices enhances reliability and reduces the risk of mechanical failure.

General Applications of PCM Heat Storage Devices

Beyond aerospace applications, PCM heat storage devices have a wide range of applications across various industries. These devices are incredibly versatile and can provide efficient thermal management solutions in the following sectors:

Building and Construction

Thermal Regulation: PCM devices can be integrated into building materials to regulate indoor temperatures, reducing the need for heating and cooling systems and thereby saving energy.

Energy Efficiency: By absorbing excess heat during the day and releasing it at night, PCM materials help maintain a stable indoor climate, contributing to energy-efficient building designs.

Automotive Industry

Battery Thermal Management: PCM devices help manage the thermal loads of batteries in electric vehicles, extending battery life and enhancing performance.

Passenger Comfort: PCMs can be used in vehicle seats and interiors to provide temperature regulation, improving passenger comfort during long drives.

Electronics and Data Centers

Cooling Solutions: PCM-based cooling solutions can be used in data centers to manage heat generated by servers and other equipment, improving energy efficiency and reducing cooling costs.

Device Protection: In electronic devices, PCM materials help prevent overheating, protecting sensitive components and enhancing device longevity.

Renewable Energy

Solar Energy Storage: PCMs can store excess thermal energy generated by solar panels during the day and release it when needed, improving the efficiency and reliability of solar power systems.

Wind Energy: PCM materials can help manage temperature fluctuations in wind turbines, ensuring optimal performance and durability.

Conclusion

The development of PCM heat storage devices represents a significant advancement in thermal management technology. At CRM Group, we are proud to be at the forefront of this innovation, working alongside our partners to provide efficient, sustainable solutions across various industries. As we continue to test and refine these technologies, we look forward to contributing to the success of future missions and the broader field of thermal management.