I-Rolls

Intelligent Roll for Monitoring Deformation and Slab Temperature in Continuous Casting

Introduction

Monitoring and controlling temperature during the continuous casting process is essential to ensure both process efficiency and steel strand quality. Large local temperature gradients can induce thermal stresses, leading to crack formation. Similarly, slab bending and unbending in unfavourable temperature ranges can cause surface and internal defects. Cooling uniformity across the slab width is also critical, especially for wide slabs, where corner overcooling can significantly increase the risk of cracking.

In parallel, roll deformation and strand bulging remain difficult to detect in real time, despite their strong impact on surface quality, internal soundness, and equipment lifetime. Early detection of these phenomena would allow operators to act proactively, reducing defects and unplanned downtime.

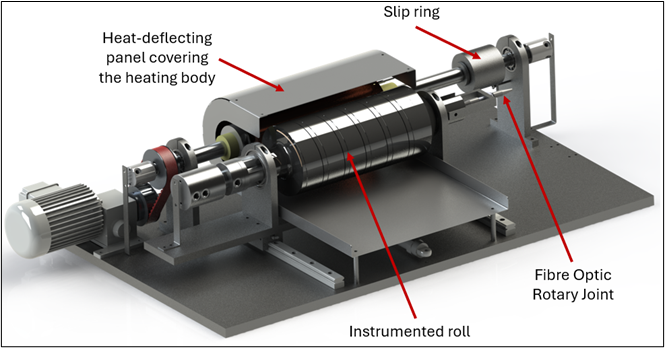

The I-ROLLS project addresses these challenges by developing an instrumented roll designed to be installed directly in the cooling section of a continuous caster. Equipped with Fibre Bragg Grating (FBG) sensors, the roll will enable continuous, in-line monitoring of roll deformation and strand temperature during casting. The project combines advanced sensing, modelling, and pilot-scale validation to pave the way for industrial deployment of this innovative monitoring solution.

Objectives

The I-ROLLS project aims to enhance continuous casting operations by enabling real-time monitoring of strand temperature and roll deformation directly inside the caster. By integrating Fibre Bragg Grating (FBG) sensors into guiding rolls, the project seeks to deliver high-resolution, in-line measurements under harsh industrial conditions, including high temperatures, water sprays, and mechanical loads.

A key objective is to ensure reliable data transmission from rotating rolls, using compact and wireless solutions capable of maintaining measurement accuracy and transmission speed. The experimental data collected will feed advanced solidification and deformation models, improving the prediction of temperature and strain fields, bulging behaviour, and defect risks such as hot tearing.

Beyond technical performance, I-ROLLS aims to demonstrate the economic viability and scalability of the solution for industrial deployment. By improving process stability and enabling predictive maintenance, the project targets reductions in downgraded products, energy consumption, water use, and unplanned maintenance stops. Dissemination and exploitation activities will ensure the adoption of the technology across the European steel industry.

Project Overview

Modelling and Sensor Integration

The project begins with advanced modelling activities led by SWERIM, focusing on heat transfer and roll deformation in the continuous caster. Conduction, convection, and radiation mechanisms are analysed using DEM for spray behaviour, CFD for boiling and vapour formation, and FEM for thermal conduction and mechanical response. These models are used to optimise sensor placement and to refine heat transfer coefficients, enabling accurate prediction of strand temperature, strain, and defect risks.

In parallel, CRM Group, TATA Steel Nederland Technology, B-SENS, and SMS Group develop and integrate FBG sensors inside rotating rolls. These optical fibre sensors allow multi-point temperature and strain measurements along the roll, offering unique insight into roll–strand interactions. Special attention is given to fibre protection, signal stability, and reliable data transfer from rotating components.

Pilot Validation and Industrial Upscaling

Pilot testing is conducted on CRM’s pilot casting facilities, where the instrumented roll is exposed to realistic operating conditions, including high temperatures, water sprays, and dust. Measurements are validated against conventional tools such as thermocouples and pyrometers, producing detailed temperature and strain maps of the strand and rolls. These data support early detection of bulging, misalignment, and abnormal deformation, contributing to predictive maintenance strategies.

In the final phase, SMS Group designs an industrial proof-of-concept prototype suitable for real casting environments. Engineering efforts focus on compactness, durability, cooling, and signal integrity. The solution is assessed for manufacturability and operational robustness, laying the groundwork for full-scale industrial implementation.

Conclusion

The I-ROLLS project represents a major step forward in the digitalisation of continuous casting. By enabling stable, in-line monitoring of strand temperature and roll deformation, the project moves beyond traditional trial-and-error process adjustments toward data-driven control and optimisation.

The expected impacts include improved surface quality, reduced downgraded products, lower energy and water consumption, and fewer unplanned maintenance stops. Scientifically, the project advances solidification modelling and understanding of phenomena such as bulging and cracking. Industrially, it strengthens Europe’s leadership in producing Advanced High-Strength Steels (AHSS) while aligning with the objectives of the EU Green Deal. Pilot demonstrations will confirm both technical feasibility and economic relevance, opening the path to industrial deployment.

This project is funded 60% by the European Commission under the RFCS programme and 40% by a collective funding programme.

Partners

CRM Group (Coordinator)