ReselScale

Role of Residual Elements on Steel Scale Behaviour

Introduction

Transitioning to zero-carbon steelmaking demands a deep understanding of the surface phenomena impacted by this transformation. The surface quality of advanced steel grades plays a crucial role in determining mechanical performance, corrosion resistance, and downstream processability, all dependent on precise control of alloying and thermal conditions.

However, the increased use of recycled scrap to enhance circularity introduces higher levels of residual elements such as Cu, Ni, Sn, and P, which significantly affect oxide scale behaviour during processing. These residuals can alter oxide growth, descalability, heat transfer, and pickling performance, posing new challenges for steel producers.

The ReselScale project tackles these challenges by producing and analysing a wide range of steel grades, both in laboratory and pilot scales, to establish clear relationships between alloy composition, processing parameters, and oxide scale characteristics. The ultimate goal is to develop comprehensive guidelines that help the steel industry maintain high surface quality while advancing toward carbon-neutral manufacturing.

Objectives

The main objective of ReselScale is to provide actionable guidance to the steel industry for managing surface quality during the shift to carbon-neutral steel production.

The project will:

-

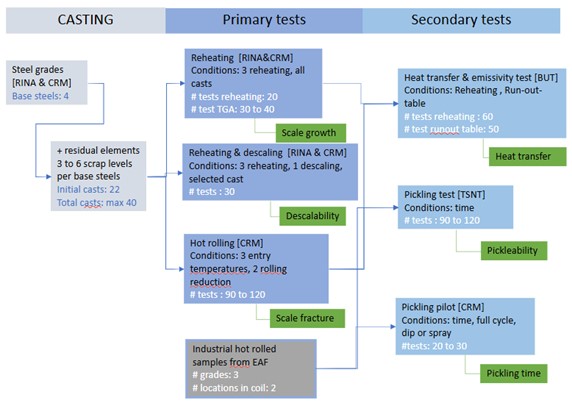

Produce and study up to 40 laboratory-cast and 3 industrial steel grades with varying levels of residual elements (DP, HSLA, low-carbon, structural steels).

-

Investigate primary oxide scale formation using multiple reheating technologies: conventional furnaces, Thin Strip Casting and Rolling (TSCR), and Endless Strip Production (ESP), including electrification and hydrogen-based reheating.

-

Conduct descaling and hot rolling simulations (over 60 trials) to assess how residuals influence descalability and surface quality.

-

Analyse pickling performance through 120 laboratory and pilot-scale tests, quantifying contamination levels of Cu, Ni, and Sn.

-

Study heat transfer coefficients in relation to scale composition and porosity using over 100 targeted experiments.

-

Develop an automated SEM-EDS image analysis tool and a machine learning model (XGBoost) to predict oxide behaviour, growth, and adhesion based on alloy and process variables.

-

Disseminate and communicate results across the European steel community, ensuring widespread access to the developed industrial guidelines for green steel processing.

Project Overview

Understanding Scale Formation in a Circular Steel Industry

The global steel sector faces an unprecedented shift toward green and circular production. With the rise of Electric Arc Furnace (EAF) and Direct Reduction (DRI) routes, residual elements from scrap are becoming a structural component of future steelmaking. These elements, while promoting circularity, complicate the control of oxide scale formation, adhesion, and removal.

ReselScale will experimentally reproduce the different industrial reheating and rolling conditions to quantify these effects, combining traditional approaches with innovative low-carbon technologies such as hydrogen combustion and induction preheating.

Experimental Scope and Innovation

The project’s methodology includes large-scale laboratory and pilot simulations covering the full chain, reheating, descaling, rolling, and pickling, supported by advanced surface characterisation and data-driven modelling.

-

Reheating trials will determine how residual elements affect oxide morphology and adhesion across different atmospheres and heating profiles.

-

Descaling experiments will reproduce industrial hydraulic descaling, exploring the combined effects of multiple residuals, a first in this field.

-

Hot rolling simulations will evaluate scale cracking, rolling-in defects, and surface roughness changes induced by element synergies.

-

Pickling trials will investigate oxide composition and dissolution mechanisms to optimise cleaning processes and bath recyclability.

-

Heat transfer studies will quantify how scale structure affects cooling efficiency and temperature control, feeding back into process modelling.

Data Analytics and Machine Learning

Through advanced image processing and AI-assisted analysis, ReselScale will transform oxide characterisation into quantifiable, predictive datasets. Automated tools will measure scale thickness, porosity, sublayers, and interfaces, correlating these with process parameters and residual concentrations.

Machine learning models (based on XGBoost) will enable accurate predictions of oxide growth, descalability, and mechanical behaviour, ultimately allowing steelmakers to simulate process outcomes for future steel compositions.

In Summary

The ReselScale project marks a major step toward achieving high surface quality in carbon-neutral steels. By combining experimental simulations, innovative heating methods, and artificial intelligence, the project aims to close critical knowledge gaps on how residual elements affect oxide scale behaviour.

Its findings will deliver industrial guidelines and predictive models to support decision-making, ensuring that surface quality remains uncompromised during the decarbonisation of steelmaking. ReselScale strengthens the foundation for sustainable, efficient, and competitive steel production in Europe’s green transition.

Partners

Tata Steel Nederland Technology B.V. (Coordinator)

Centre de Recherches Métallurgiques (CRM Group)

Brno University of Technology (Vysoké Učení Technické v Brně, BUT)

Acciaierie d’Italia S.p.A. (in Amministrazione Straordinaria)