Structural optimizations

As part of the energy transition, structural optimizations are of importance to reduce the carbon footprint. CRM group can optimize several types of structure using high strength steels. These steel grades showing higher mechanical properties than the common steels allow thickness decrease leading to weight reduction. As steel quantities are minimized, the CO2 emissions decreased in the same way. Another benefits with these added-values products is the cost savings which may result.

What are the objectives ?

Two types of optimizations can be carried out:

- an iso-performance objective compared with the reference solution achieved with a mass reduction

- an iso-mass objective compared to the reference solution with a higher performance

Whatever the target, different analyses are carried out using finite element software :

- ULS – yielding

- ULS – buckling (LBA, MNA, GMNA, GMNIA)

- SLS

Which are the most common. Frequency analyses or fatigue analyses, depending on the structures and solicitations, can also be undertaken. Structural checks are carried out on the basis of standards used in each field. For all these projects, several iterations are performed to find the best compromise.

Tools & Applications

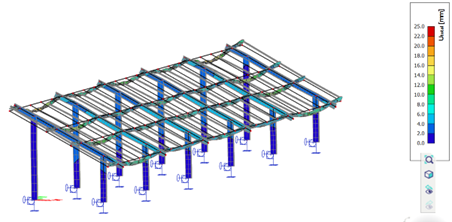

This kind of optimization is applied to all steel structures types. Among others, studies have been performed on solar structures (either fixed or tracker), carports, pylons, wind towers, silos, racking systems, …

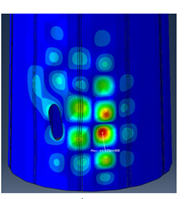

Finite Elements (FE) software support those analyses. Global or local analyses can be carried. Sub-models can help to further analyze some details as for example connections (bolted or welded), openings, … All those FE results can be correlated with experimental test campaign carried out within CRM lab.

Pylons

Solar PV fixed structures

PV trackers

Wind towers