Unique infrared pyrometer calibration laboratory

Calibration and verification of key measurement tools used during your production process are vital for delivering high quality products to your customers. One of such critical measurements in metal production and multiple other applications is temperature. Whether to control a process or to visualize certain inhomogeneities, temperature deviations can have a very specific impact on your final product.

Did you know CRM Group has the only Belgian BELAC accredited laboratory for performing these temperature measurement calibrations according the international ISO/CEI 17025 standard?

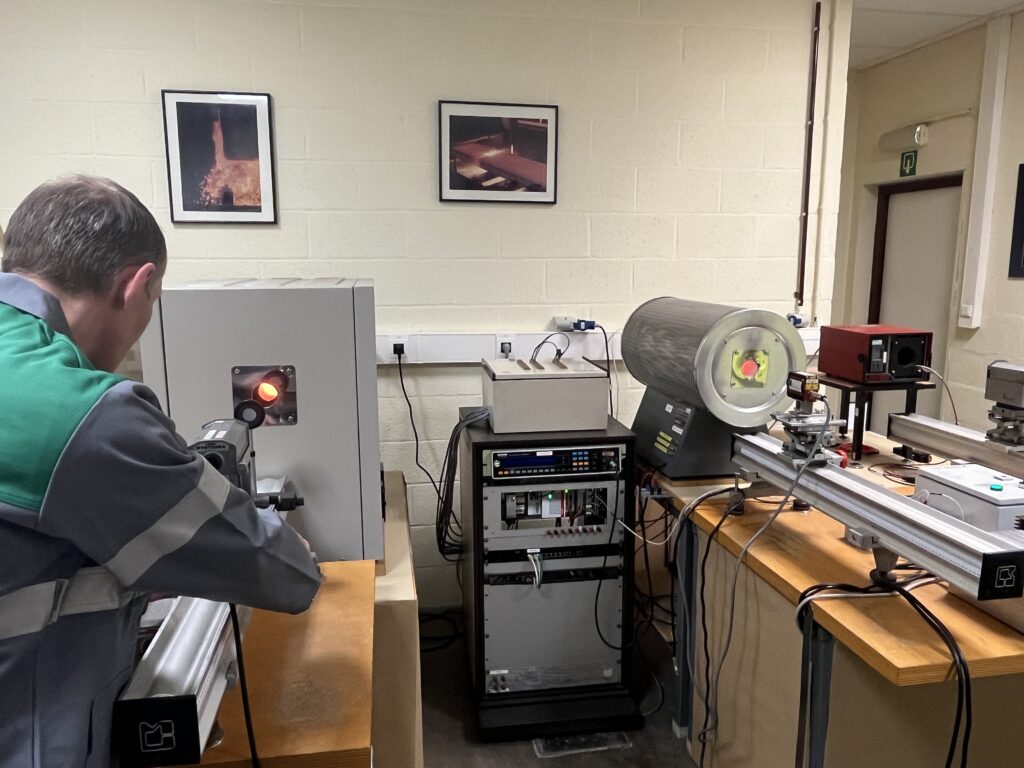

Our facilities are unique in Belgium and are equipped with 3 high stable black body furnaces with an emissivity above 0,998. Two standard pyrometers and one standard Platinum resistance thermometer allow us to cover a scope from 50°C up to 1600°C. More specifically the range between 300°C and 1600°C is accredited by BELAC certification for which more details can be found here.

How to ensure that your spot or online temperature measurement tool is yielding correct values within a certain range?

A very wide range of brands and models of infrared pyrometers can be verified and if required calibrated, including short and broad wavelength equipment, two colors and multiwavelength pyrometers as well as line scanners and thermographic cameras.

On several types of equipment we can even tune the calibration curve if the required technical details and features are known by our calibration team.

Who can access this service ?

Our current clients are both metal producers as well as other sectors that use temperature control in their process. They can certainly witness of our excellent service with a dedicated team. Both Belgian and European companies are welcome to use our services as long as their equipment can be dismounted and sent to our laboratory in a safe way.

Who should I contact for this service ?

Just send an email to asking for pyrometer calibration and adding a short description of your equipment. Following that we will check in detail with the technical team your temperature measurement tool specifications and supply a price and delay time.