Caesar

Circularity enhancements by low quality scrap analysis and refinement (CAESAR)

Objectives

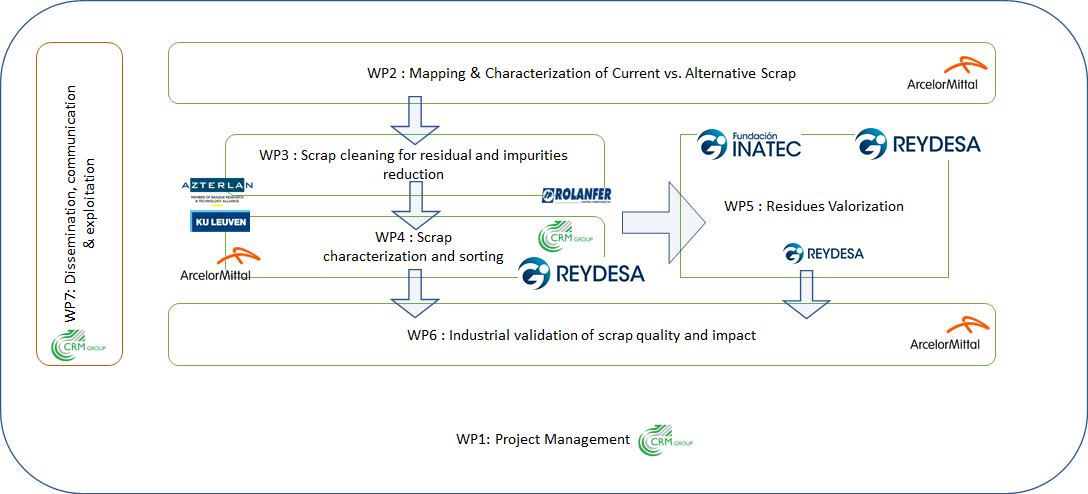

The main expected outcome of CAESAR will be the demonstration at full-size industrial scale of integrated scrap upgrading, sorting, and characterisation technologies, untapping volumes of low-quality scrap streams in Europe and generating valorisation routes for all the non-ferrous fractions obtained, towards zero waste. The more specific objectives are:

- Identify and characterise new opportunities to use and reuse lower-quality scrap

- Select and integrate the best available technologies to upgrade, sort, and characterise lower-quality scrap

- Validate an industrial demonstrator of scrap sorting/cleaning, based on innovative combination of BATs

- Define valorisation routes of the waste generated by the demonstrator

- Define and implement an exploitation strategy to realise the project’s business case

Description

The scrap usage in the steel sector is a common practice to improve the process’ sustainability, as it decreases the use of virgin raw materials i.e., iron ore and boosts the circular economy by using waste produced in the steel process

and other value chains. Pre-consumer scrap i.e., directly reusable scrap generated in steelmaking, represents roughly

45% of the total scrap used worldwide, whereas 55% of the scrap utilised comes from other processes and contains various type of pollutant (inert materials, other metals, plastics, etc.). This is called post-consumer scrap.

The current trend in the EU scrap market points at a slight decrease in the pre-consumer scrap (due to production i.e.,

yield, improvement, meaning less scrap production by tonne of steel) and an increase in the short- and long-term of the post-consumer scrap stream, due to an increase in steel consumption. At the same time, the scrap demand from the steelmaking industry is sharply increasing as producing steel from scrap (by increasing either EAF production share or the scrap ratio at BOF) drastically reduces CO2 emissions and energy consumption. Unfortunately, the quality of the scrap needed to meet high-quality steels standards limits dramatically the use of post-consumer scrap, with End Of Life products’ streams that are growing not only in volumes but in complexity (containing unwanted minor elements such as plastics, fibres, metals, etc.) and decreasing in quality.

To increase the steel scrap recycling capacity and energy efficiency, while keeping EU competitive and safe in terms of raw materials imports, energy consumption and climate change impact, innovative technologies to “clean” the scrap before it reaches the steel furnaces need to be implemented. To this aim, CAESAR’s focus is to reduce impurities in post-consumer scrap before melting together better classified scrap, to increase the use of scrap, achieving the same quality of the finished product.

The research leading to these results has been performed within the CAESAR project (website address) and received funding from the European Community’s Horizon 2020 Programme (RFCS) under grant agreement n° 101058520

Partners

Funding Bodies