MaterHYum

Building a Testing Platform for Hydrogen-Compatible Materials & Components

Introduction

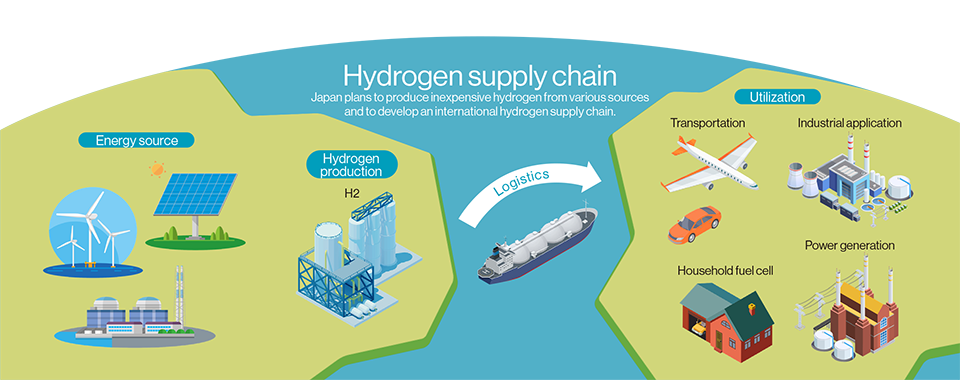

The rapid development of hydrogen technologies requires new knowledge, particularly regarding the compatibility of materials with hydrogen under real operating conditions. As hydrogen becomes a cornerstone of the energy transition, industries must ensure that materials and components can withstand demanding environments of pressure, temperature, and cyclic loads.

The MaterHYum project, led by BeBlue and CRM Group, directly addresses this challenge. By developing advanced expertise and dedicated high-pressure hydrogen testing facilities, MaterHYum aims to provide industry with a unique service: the validation and certification of materials and sub-components under representative hydrogen conditions.

Objectives

The primary objective of MaterHYum is to accelerate the market launch of a new validation and certification service for hydrogen-related materials and components. This includes:

-

Validating and certifying materials and (sub-)components under high-pressure gaseous hydrogen in real-life operating conditions.

-

Offering industrial stakeholders access to advanced testing capabilities and expertise to support the development of next-generation hydrogen-compatible materials.

-

Strengthening the Walloon hydrogen value chain by providing cutting-edge infrastructure that positions the region as a competitive hub for hydrogen research, development, and industrial deployment.

Project Overview

A State-of-the-Art Hydrogen Testing Platform

To address the critical need for hydrogen-material interaction assessment, MaterHYum is establishing a comprehensive testing platform capable of reproducing industrially relevant conditions of pressure and temperature. The facilities will include:

- Hydrogen autoclave ageing tests: up to 100 bar H₂ at 450°C and up to 700 bar H₂ at 200°C.

- Cryogenic tensile-fatigue tests: simulating extreme low-temperature operating environments.

- Tensile-fatigue tests under hydrogen: up to 500 bar H₂ between -20°C and 200°C.

- Permeation tests: up to 1000 bar H₂, providing critical insights into hydrogen diffusion through materials.

This unique combination of test capabilities will allow industry to qualify materials and components under the most challenging hydrogen service conditions. The full platform is expected to be operational by 2026.

Supporting the Hydrogen Value Chain

MaterHYum contributes directly to the growth of the hydrogen ecosystem in Wallonia and Europe. By providing advanced testing and certification capabilities, the project helps derisk technology development, shorten time-to-market, and attract industrial and research partnerships.

It also aligns with broader European goals for decarbonisation, energy transition, and the safe deployment of hydrogen technologies across multiple sectors, including energy, transport, and heavy industry.

Conclusion

MaterHYum represents a decisive step toward strengthening Europe’s hydrogen economy. By enabling the validation and certification of materials and components under real hydrogen operating conditions, the project ensures safety, reliability, and performance. The partnership between BeBlue and CRM Group positions Wallonia as a leading provider of hydrogen testing services, supporting both industrial competitiveness and the transition toward a sustainable, low-carbon future.