PyroTeCnIC

Pyrometallurgy and intelligent conditioning techniques for the circular economy

Objectives

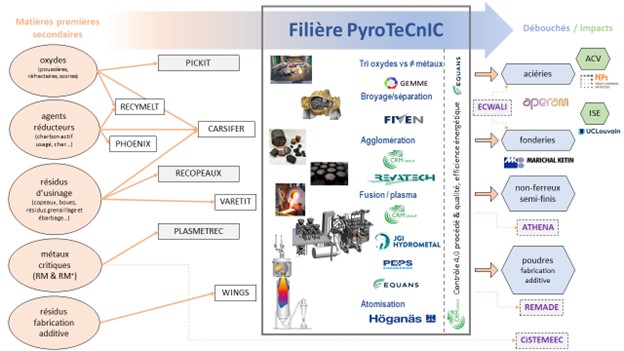

The PyroTeCnIC project aims to showcase Wallonia’s expertise in pyrometallurgy, serving the circular economy and boosting competitiveness. The project focuses on locally producing alternative sources of alloying elements (Cr, Ni, Mo, V, W, Nb, Co…) from industrial residues, incorporating plasma furnace technology into hydrometallurgy for improved recovery of critical metals, and adapting metal powder production through atomization to meet recycling needs.

Description

The PyroTeCnIC project aims to promote Walloon expertise in pyrometallurgy, serving both the circular economy and competitiveness. The project focuses on locally producing alternative sources of alloying elements (Cr, Ni, Mo, V, W, Nb, Co…) from industrial residues, integrating plasma furnace technology into hydrometallurgy for improved recovery of critical metals, and adapting metal powder production through atomization to meet recycling needs.

Custom-made briquettes from residue rich in alloying elements will be developed to serve as secondary raw materials for companies such as Aperam (stainless steel production), MK (rolling mill cylinders), and even Höganäs (metal powder production). Several partners, supported by CRM Group, will explore the synergistic combination of various pre-treatment steps to diversify and scale up supply chains:

-

Fiven will develop grinding-sieving-magnetic separation processes, particularly to extract embedded metals from slags or used refractories.

-

The PickIt robotic sorting system from ULiège-GeMMe will separate valuable sub-streams.

-

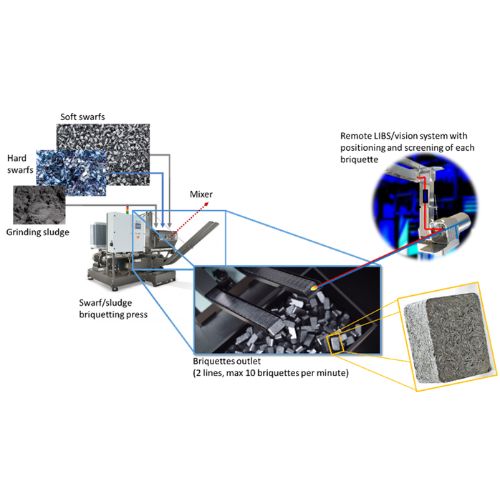

Revatech will focus on briquetting materials from Fiven and others, such as crushed batteries, dust, shot blasting residues, and machining waste.

As part of the ongoing Plasmetrec project, CRM and Hydrométal are developing a unique combination of pyrometallurgy (plasma furnace) and hydrometallurgy to process a wider variety of industrial residues, including those containing low concentrations of non-ferrous metals. The exponential demand for critical metals driven by the energy and digital transitions presents Hydrométal with new opportunities to diversify its activities. The flexibility of the plasma furnace will enable the development of processes tailored to complex niche streams (e.g., small unsorted batteries). The pre-design of an industrial unit will be carried out by Peps Engineering.

Höganäs will investigate integrating vacuum technology during the melting stage, combined with high-pressure atomization, to accommodate secondary materials sourced from Revatech, Hydrométal, or by recycling its own powder residues after agglomeration.

Digitalisation will ensure high performance despite the inherent variability of recycled materials and the complexity of the processes involved:

-

Equans will collaborate with CRM to develop a Digital Twin of the plasma furnace at Hydrométal.

-

CRM will design specific online instrumentation to control the quality of briquettes at Revatech.

All developments will be brought to TRL8 (demonstrator level). Preliminary business plans have been established by industrial partners for the associated recycling sectors, with a total estimated investment of €52 million (2021 figures). CRM is also considering the creation of a spin-off to commercialize the online briquetting instrumentation.

The implementation of this industrial plan is expected to generate 57 direct FTEs and 114 indirect FTEs, not including jobs potentially safeguarded through increased competitiveness.

Partners

Funding Bodies