Circular economy and recycling of metals

Manufacturing new added-value products through the recycling, processing or re-use of end-of-life goods and byproducts is one of the ambitious but necessary objectives of the modern industrial economy, a target of particular importance for Europe.

Rheological characterisation and viscosity measurments

The precise knowledge of the rheological characterisation of the slag is one of the important aspects impacting the slag properties and conditioning the development of new slag processing.

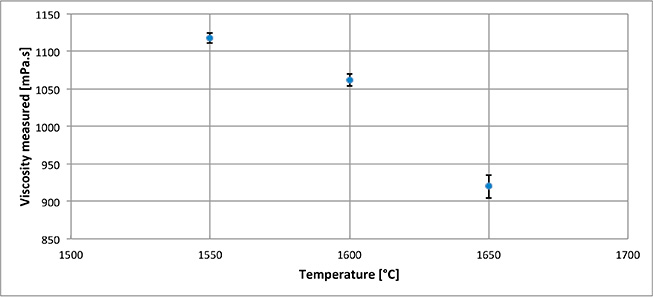

High tempertaure rheometer allowing to measure the viscosity and other properties of metal and slag at different temperatures between 600°C and 1650°C.

Example of viscosity measurements realized on a blast furnace slag.

Recycled material processing

The mixing of by-products coming from different industrial sectors (Ferro-manganese production, Steel industry and Car recycling) to valorize their metallic and organic content and deliver new added-value ferro-manganese alloys.

Recycled material processing

CRM is actively engaged since few years in the development and implementation of new recycling approaches, with a strong support of the Walloon Government (”Reverse Metallurgy” project) and the European Community (“EIT Raw Materials” program).

Recycled material processing

The Steel and Metal industries are natural key players of the “Circular Economy” approach as they supply a large part of the products used in many applications and markets all around the World and already recycle a large part of this production. Despite this positive position, it appears mandatory to pursue the effort for further improving the situation and promoting better adapted recycling solutions as the modern goods and products are becoming more and more hybrid and complex notably for what concern the amount and number of metals and materials entering in their design.